The most demanding expectations of the dairy industry, find at DIMA the adequate and equally sophisticated production solutions to fulfill all medium and high production capacities requirements in reliable way.

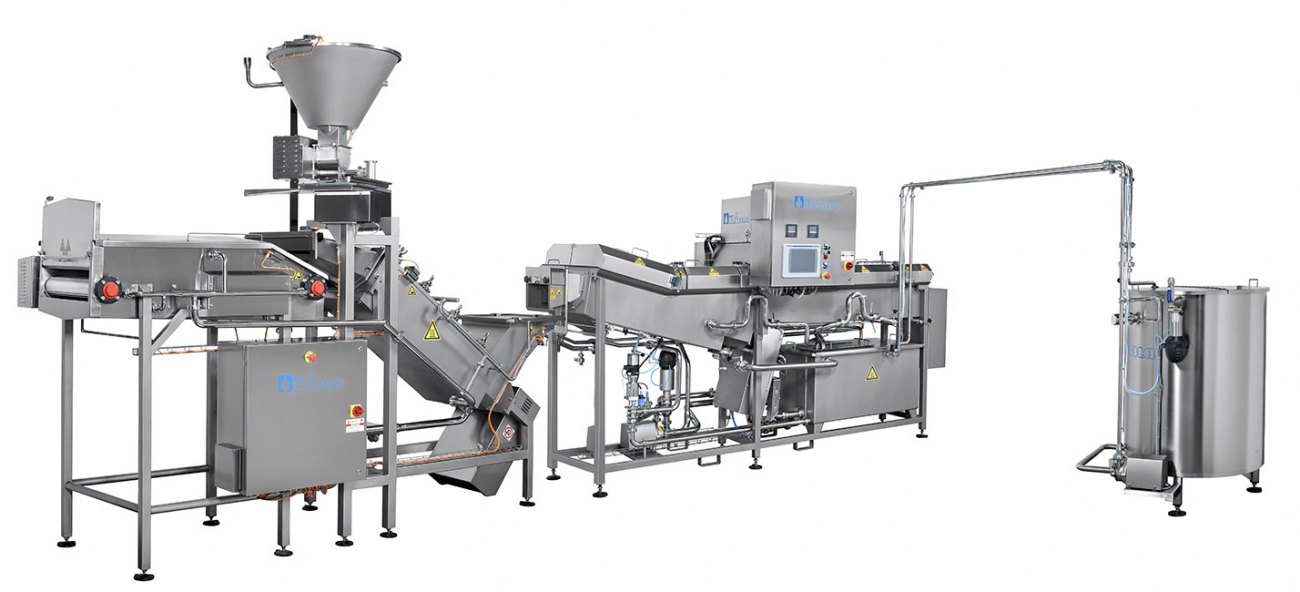

The cooker and stretcher machine mod. DM1231/CIP is specifically designed for the continuous cooking stretching and kneading of quality and wide variety of “pasta filata” cheese types. In particular for producing stretched cheese with low and medium moisture content as pizza-cheese, shredded mozzarella, provolone, kashkaval, kasar.

The machine integrates the cooking water preparation, heating and circulation group and prearranged for automatic C.I.P. cleaning.

Features

- Perfect solution for industrial productions

- High production rate, flexibility and excellent proven performance

- C.I.P. perfectly cleanable

- Continuous and constant working process

- Water cooking stretching machine

- Equipped with gentile mixing pre-cooking section with couple of horizontal contra-rotating augers with adjustable speed to comply with the production requirements

- Equipped with cooking and stretching section with two contra-rotating inclined augers with adjustable speed to meet the production requirements

- Equipped with innovative system to eliminate possible water bubbles formed inside the cheese mass to ensure homogenous product

- Equipped with a special device allowing to adjust the product extrusion pressure

- The flow and quantity of the cooking water is adjustable in accordance to the production capacity and product’s specifications and characteristics

- Automatic control of the temperature of the cooking water - Includes the vat for preparing, heating and recirculating the water necessary for cooking & stretching

- Equipped with frequency converters which make the operation extremely simple. Speed regulation done via push buttons located on the control panel.

Optional features

- Curd slicer (mod. DM02/CIP) directly assembled on the cooking stretching machine or on a supporting structure

- Curd block cutting with vertical cutting of the curd (mod. DM02-V/CIP)

- Auger curd elevator (mod. SP31/CIP)

- Curd feeding through curd cyclone by air blowing

- Automatic system for control and adjustment of the acidity of the fat water

- Automatic system for salt control and adjustment of salt in the cooking water

- Automatic control of outfeed cheese temperature

- Control panel for automatic control PLC with touch screen HMI

- Indirect heating of the cooking water through overheated water / or steam (indirect steam)