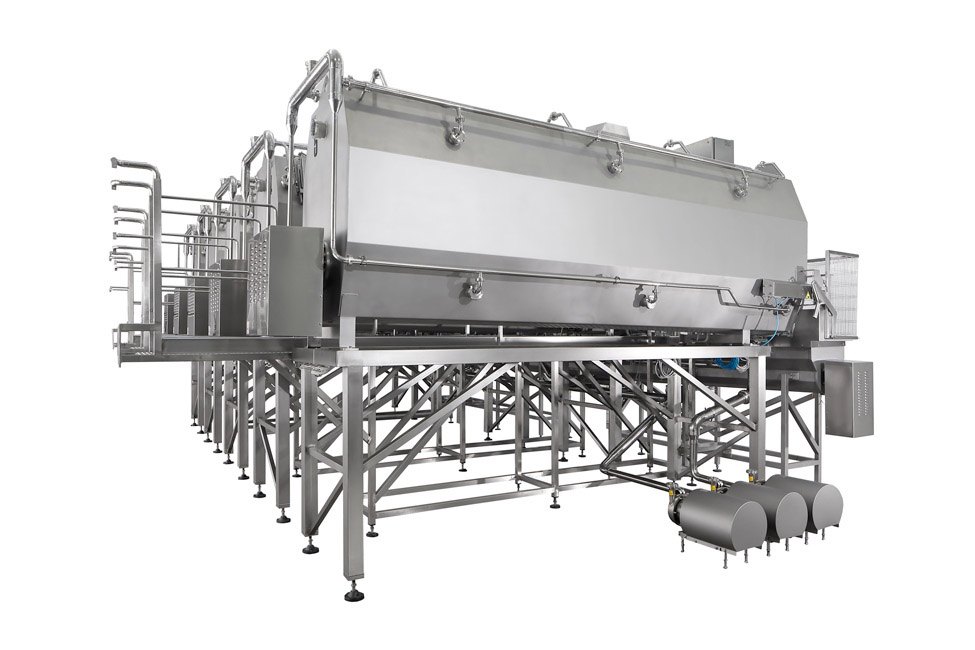

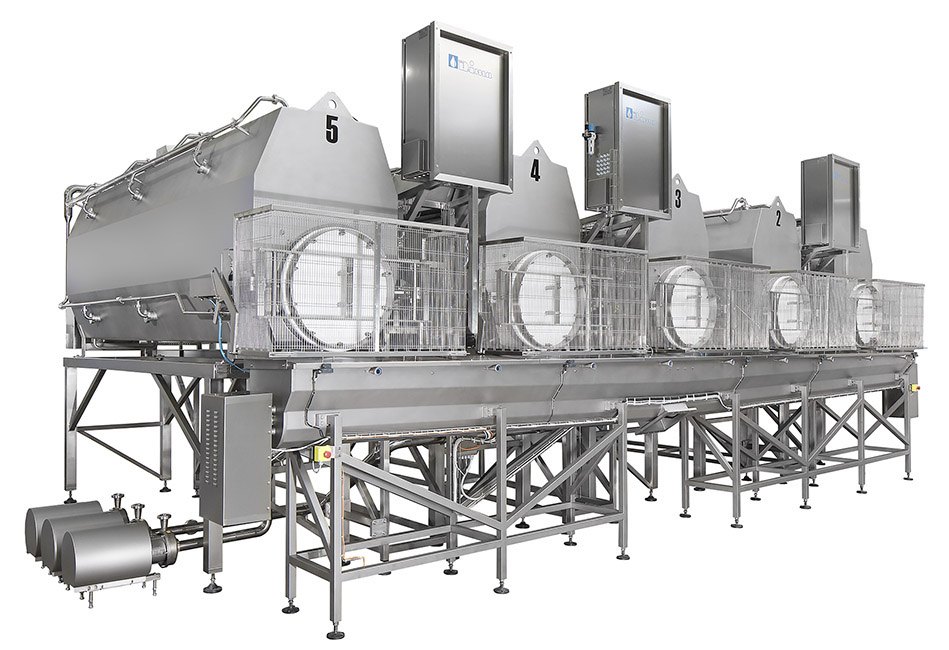

Automated DIMA’s system for curd draining and maturation specifically designed to receive the mixture of curd and whey from the cheese vat (or vats) and hold the curd for ripening until it reaches the desired acidity. During the acidification process, it is possible to keep the curd under partial or total whey, without whey or even for some time under whey then without whey.

Once the maturation is achieved, the whey is drained off and the curd is transferred through the curd slicer into the transport system (auger conveyor, belt conveyor or curd blowing system) in order to feed automatically and continuously the cooking-stretching machine.

This system is particularly suitable for mozzarella and stretched cheese production using starter bacteria acidification’s technology or a mix with also direct acidification.

- Modular construction

- Constancy and homogeneity of the curd feeding with the same consequence on the product quality

- Fully automatic system (no manual handling of the product)

- Production capacity adjustable as per Customer’s needs

- Closed and hygienic design, allowing however operator’s inspection for monitoring the process, following the latest industrial hygienic and safety requirements

- The closed construction of the system ensure a stable temperature to the curd environment which contribute to boost the ripening process

- C.I.P. perfectly cleanable

- Automatic control with PLC control of the working and cleaning phases .